Analysis Of The Advantages, Disadvantages And Limitations Of Different Evaporators

Low-Temp evaporation technology originated from Israel in the late 1970s-low temperature multi-effect distillation technology. It developed from the traditional multi-effect evaporation. Later mechanical vapor recompression technology(MVR), multi-effect evaporation technology(MEE), low-temp vacumm heat pump evaporation technology(V-HP)appeared. However, according to the present environmental protection requirements, the limitations of traditional environmental protection technology have also started to appear, such as treatment scale, treatment effect, occupation, operating costs etc.

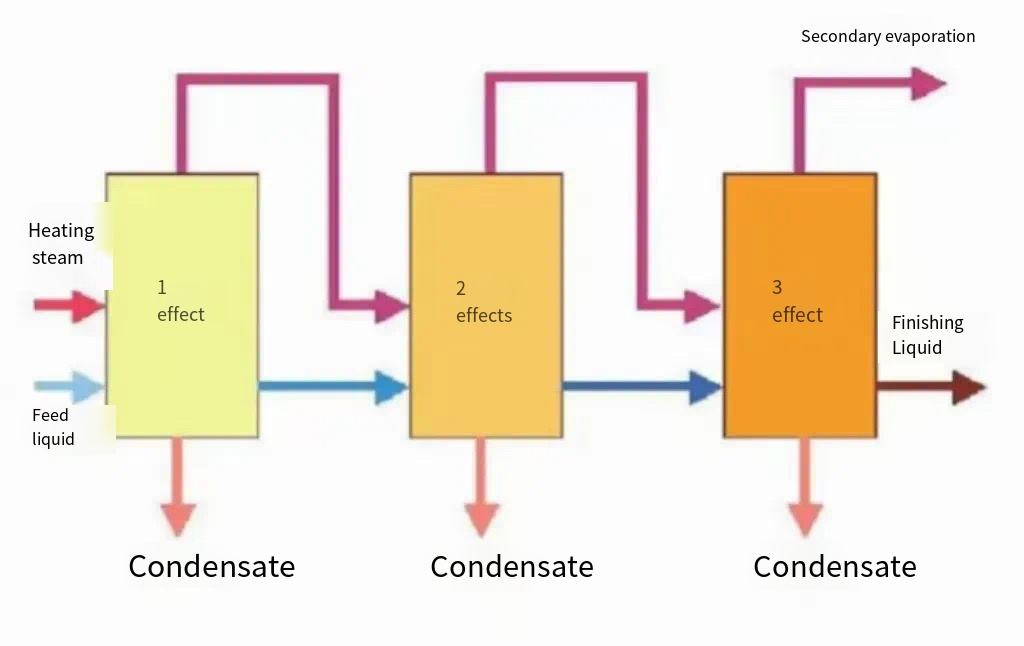

About MEE:

MEE technology is to run several evaporators in series, and the steam heat energy can be used many times, to improve the utilization rate of heat energy.

Advantages: evaporating in a very short time, the effect of multi-effect evaporation will be very good. At the same time, it has a long service life and can reduce a lot of costs.

Disadvantages: machines are heavy with much more parts, disassembly and installation are more troublesome. The working principle is more complicated, the tempreture needs to be watched all the time,so humans have to be around. What’s more, it’s also complcaited for non-professional technicians to operate, it leads to much higher labor and maintenance costs.

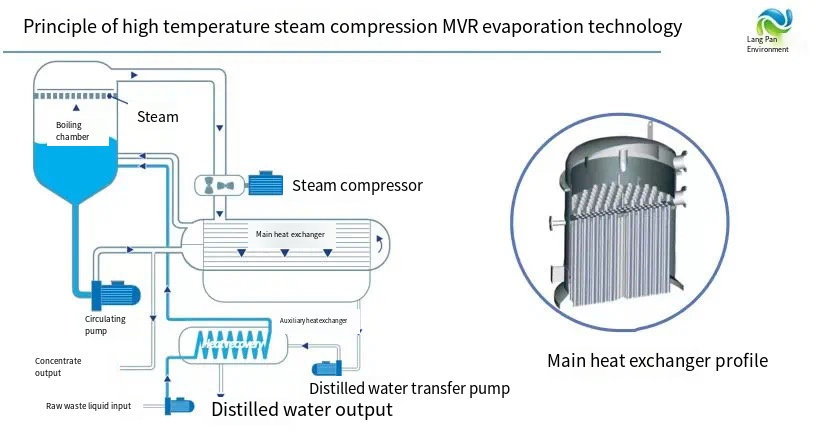

About MVR:

Advantages: 1, the consumption of a small amount of steam, low operating costs;

2, less engineering support;

3, easy to start, simple operation, stable operation;

4, simple structure, low operating cost.

Disadvantages: 1, MVR evaporator initial investment is high. The core of MVR equipment is steam compressor,while the price range of domestic compressor and foreign compressor is large, so a major disadvantage of MVR evaporator is expensive or poor steam effort.

2, Good performance has strict conditions. Only in the condition of small effective temperature difference with large heat exchange area , the equipment value will be higher. The tube heat exchanger is difficult to be disassembled and clean. At high temperature, calcium and magnesium ions formed much more, and relatively dense, difficult to clean.

3, The quality of manufacturers is intermingled. At present, there are many non-produce companies in the market which subcontacted the project to the OEM. The pre-plan and the later technology couldn’t be combined well, making the project run unstable, and even leading to a lot of MVR evaporators fail to operate.

About V-HP (Low-Temp Vacumm Heat Pump Technology)

Advantages: 1, Stable material, good quality of condensation and could get into post-treatment directly,

2, Low temp and negative pressure make more reliable operation,

3, Integrated design, lower occupation, plug& play,

4, Remote control with lower manpower,

5, Not easy to produce sacling, automatic regular cleaning,

6, The compressor indirectly acts on the material through the refrigerant to heat transfer, without direct contact, slow corrosion at low tempretrure. Lower scalling,easier cleaning and maintenance.

Disadvantages: The capacity of a single V-HP evaporator only be 30 tons/day.

The complex materials determine that only one solution can rarely meet the needs of customers, and it is difficult to ensure the stable operation of the system. LongHope Environmental can provide customized solutions, including pre-treatment, advanced treatment and targeted cleaning maintenance and other necessary auxiliary processes, to provide customers with a full range of products and technical services.